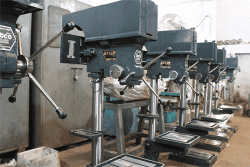

Tapping as done by Tapping Machines is a process in which two pieces of metal are fastened together. The machines also drill a hole where screws are utilized. Using a tapping machine makes it possible to do several tasks whilst saving labour and time. The machine is used on automobile parts, electronics and industrial machinery, but most of the time, tapping machines are used when big loads need to be drilled. Some advantages of tapping machines are the following:

- Tapping machines are easy and fast to install without needing an added skill to do the job.

- They are extremely versatile and multi-faceted. As per predetermined depth, they ream and screw well.

- A top advantage of tapping machines is that they require low maintenance in order to achieve long lasting results.

- Tapping machines are made of high-quality components such as spindles, gears and shafts.

- Another benefit is that there are no extra attachments or accessories needed in order for the machine to work as efficiently as possible.

- Lastly, there is a feet switch facility to be used in case of an emergency.

As the tapping machine involves drilling as well as tapping, mass production is easily achieved. As long as the handlers of the machine have sufficient knowledge of the machine, there is limited risk of any kind of damage during operation. This is possible only under the expertise of professionals such as those at Cotswold Machinery Sales. As stated on their website, they are specialist providers of ‘The world’s leading manufacturer of tapping arms.’ They have ‘A broad selection of high quality tapping arms at competitive prices [and] Electric and pneumatic tapping arms to choose from.’