Some of the more traditional methods of bonding together metal items, such as forging, brazing and soldering are still in use today. But, newer bonding solutions such as Metal bonding adhesive or film, from companies like CT1 now mean that there are more ways to accomplish metal to metal bonding than has ever been possible before. If you were wondering which method to choose here are some of the advantages and disadvantages of each.

Fastenings of Metal

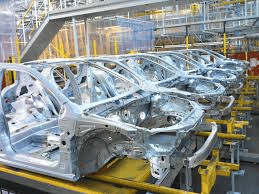

This type of fastening can be achieved using robotics which means they can be achieved in quicker time frames. But metal fastenings tend to place strain on some material points, which can lead to unequal distribution of loads in turn. When mechanical fastenings are used, rusting can also occur, when metals rub together and oxidation is made possible by the holes that are needed to join the two metals together. This will harm the material integrity and the aesthetics of the finished products.

Thermal Joining

This is a labour-intensive option that requires expert skills, resources and machinery. In contrast with mechanical fastenings, welding provides a more compact and tidy appearance and it is not impacted upon in terms of stress occurring on particular joints where screws and nails are used.

Adhesives

Metal adhesive bonding has many benefits over conventional types of metal-to-metal bonding. Adhesives ensure an equal distribution of the load, meaning no stress on joint areas, and will guarantee the integrity of thin metal sheets remains in place. Which means the occurrence of rust is less probable. Less skilled manpower, machinery and infrastructure are also needed, saving money for manufacturing industries in the long run.