One of the most important things to remember is that there are a lot of different things that go into making a piece of sheet metal. The main reason why people can’t get a nice bend in the piece of metal that they want is because of a few different factors that will cause the sheet metal to either snap or come apart entirely. When you are looking to learn how to achieve a perfect bend, it is important to take the time to understand the entire process.

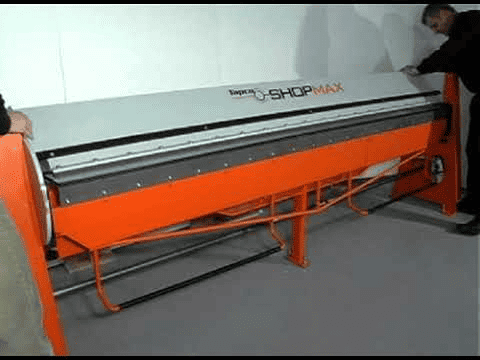

You first have to understand what exactly goes into getting a sheet metal bend. This is very important because this will be one of the most important factors when you finally decide to try your hand at doing it. The most common method that is used for doing this is using Bending Machines. Find out more about these machines at a site like Cotswold Machinery Sales, suppliers of Bending Machines.

The next part of the process involves bending the material into the right shape. Once you get the piece of metal to the desired shape, the next step involves making sure that it is properly held back in place after it is bent. This is done by putting a very strong clamp on the end of the piece of metal where you want the bend to happen. This is an important process in the fabrication industry as it’s important to bend metal for the production of all kinds of products.