Composite electroless nickel coatings can be used to add a range of useful properties to components across a wide variety of industries. Because of its unique benefits, the electroless method is both an effective and cost-efficient way of creating uniform coatings on all sorts of materials, of all different shapes and sizes.

It has even gained attention in recent years for its use as an electrocatalyst in the production of renewable energies.

Different nickel composites can be used to give the maximum coating performance for a particular application, including nickel PTFE, nickel boron and nickel diamond plating. Reputable suppliers of plating services, such as poeton.co.uk/advanced-treatments/apticote-460-nickel-composites, will be able to advise on the most suitable choice of nickel composite coatings to best meet the requirements of the application.

The following is an introduction to commonly used coatings.

Electroless nickel/ PTFE

A nickel composite coating containing polytetrafluoroethylene (PTFE) can be used to combine the desirable properties associated with electroless nickel with those of PTFE. An electroless nickel surface coating typically gives a very hard finish, and PTFE has the ability to add lubricity.

This combination of the two clearly creates useful components for many different industries including aerospace, automotive, machinery manufacturing and many other different types of engineering. Nickel PTFE has high resistance to wear from friction and is self-lubricating, which makes it an obvious choice for applications where sliding parts experience wear, and for situations where more conventional lubricants might cause component damage.

Nickel diamond

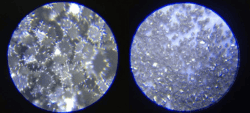

Nickel diamond composite coatings consist of an electroless nickel layer containing extremely fine diamond particles. This is a very cost-effective technique because the properties of diamond are added to a component’s surface, resulting in a high resistance to both wear and corrosion.

Nickel boron

Electroless nickel is also commonly used in combination with boron to produce an alternative option to plating with chrome. This coating has excellent corrosion resistance, is very hard-wearing and also reduces both the friction and drag experienced between sliding surfaces. Another advantage is that its coarse, grainy surface encourages heat to dissipate very effectively.