Plasma spray coating is a dynamic and versatile process utilised across a myriad of industries for the application of protective coatings.

Understanding Plasma Spray Coating

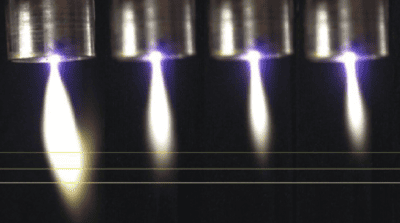

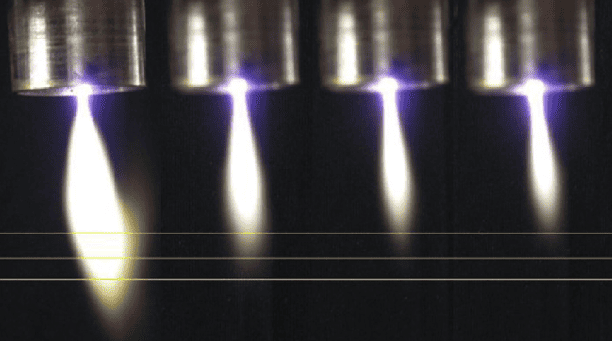

Plasma spray or thermal plasma spray is a process which involves the application of molten or semi-molten material onto a substrate using a high-temperature plasma flame.

At the core of this process is the interaction between the plasma flame and the coating material, which is crucial for the formation of a dense and durable coating. The energised particles within the plasma play a significant role in facilitating the coating’s formation, enabling the material to melt or soften before solidifying upon impact.

Benefits of Plasma Spray Coating

According to Mechanical Hub, plasma spray coating offers numerous advantages. By precisely controlling the plasma parameters, a surface treatment specialist such as Poetons can tailor coatings with specific properties, such as hardness, wear resistance, and corrosion protection. Additionally, the process allows for the deposition of thick coatings with excellent adhesion, even on complex geometries and heat-sensitive materials.

Applications of Plasma Spray Coating

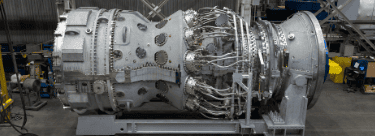

Plasma spray coating finds widespread use in industries such as aerospace, automotive, energy, and manufacturing. It is employed for purposes ranging from thermal barrier coatings in gas turbines to wear-resistant coatings on engine components. Additionally, plasma spray coatings are utilised for refurbishing worn-out parts and extending the service life of critical equipment.

So, there you have it. Plasma spray coating is a versatile and effective process with numerous applications across industries. Its ability to enhance surface properties and provide durable protection makes it a valuable asset in various engineering and manufacturing applications. By understanding the fundamentals of plasma spray coating and its interaction with the plasma flame, engineers and professionals can harness its potential to address a wide range of surface protection and enhancement needs.